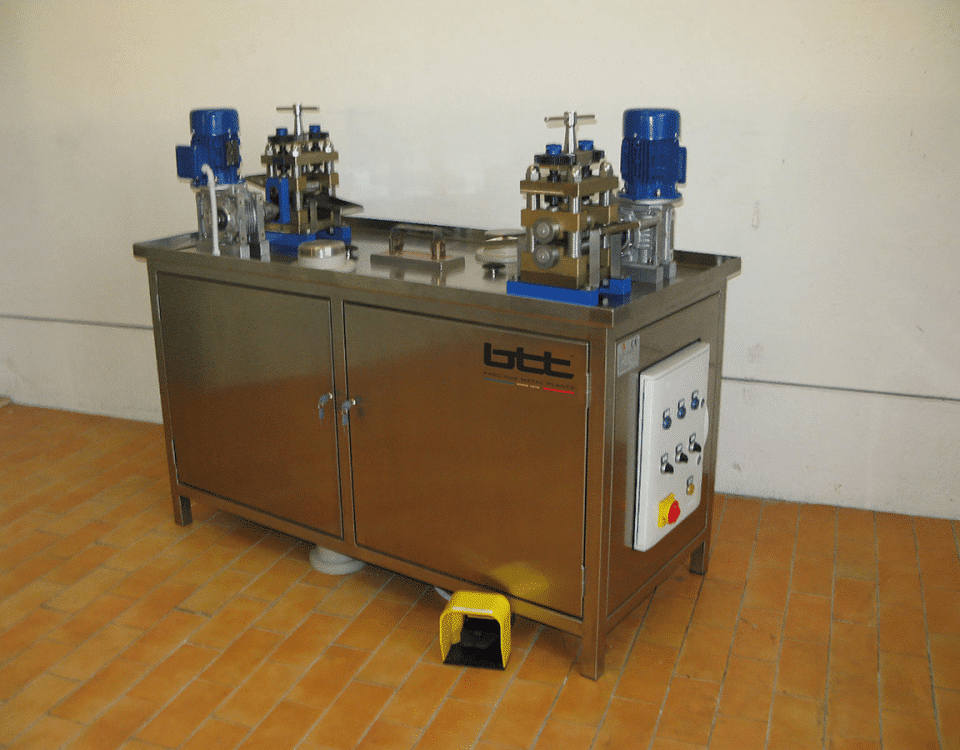

Process water treatment plants: efficiency and sustainability in precious metals processing

The importance of process water treatment

In the precious metals processing industry, process water treatment plays a crucial role. During refining, electroplating and other processing, large amounts of water are used, which, if not treated properly, can contain metal residues and potentially harmful chemicals.

Process water treatment plants make it possible to recover valuable materials, reduce environmental impact and comply with current regulations, offering highly efficient and customized solutions for every industrial need.

How do process water treatment plants work?

These plants are based on a combination of advanced technologies designed to remove contaminants and recover valuable materials found in wastewater. The main processes involved are:

- Filtration and separation: removal of solid particles and oils in the water.

- Chemical precipitation: separation of metals through chemical reagents.

- Ion exchange: use of resins to remove metal ions.

- Reverse osmosis and ultrafiltration: techniques for obtaining ultrapure water that can be reused in production processes.

- Electrolysis: recovery of precious metals found in industrial wastewater.

The integration of these technologies results in effective treatment, minimizing water waste and operating costs.

Advantages of process water treatment plants

The adoption of advanced process water treatment plants offers numerous advantages:

- Precious metal recovery: processes such as electrolysis and chemical precipitation enable the recovery of gold, silver, platinum and other valuable metals from wastewater.

- Reduced environmental impact: water treatment avoids contamination, contributing to environmental sustainability and compliance with current regulations.

- Optimization of operating costs: reduction of disposal costs and possibility to reuse purified water within production processes.

- Regulatory compliance: ensures compliance with local and international environmental regulations, avoiding penalties and reputational damage.

Applications in the precious metals sector.

Process water treatment plants find application in various stages of precious metals processing, including:

- Refining and recovery: they treat water from precious metal purification processes.

- Electroplating and plating: they remove chemical and metal residues from solutions used in electroplating baths.

- Alloy and semi-finished product production: they reduce waste and enable the recovery of precious materials from rinse water.

Regulations and environmental sustainability

Environmental regulations are becoming increasingly stringent, and companies involved in precious metals processing must adapt to high standards of safety and sustainability.

Implementing process water treatment plants not only avoids penalties, but also represents added value for the company, improving its image and contributing to a more responsible production model.

Conclusion

The adoption of process water treatment plants is essential for companies in the precious metals industry. Thanks to advanced technologies, these solutions make it possible to recover valuable materials, reduce environmental impact and optimize operating costs. Investing in state-of-the-art plants means ensuring a sustainable, efficient and regulatory-compliant future. Contact us to discover the best solutions tailored to your business!