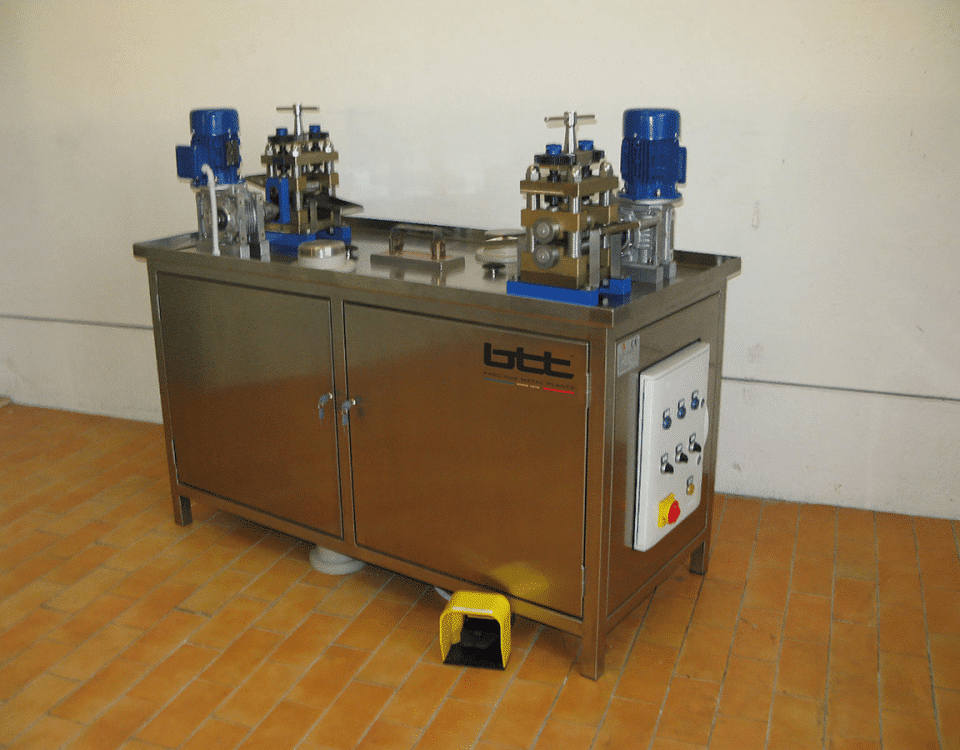

Precious metal recovery and refining machine plants: technology and innovation

In the precious metals recovery and refining industry, technological innovation plays a crucial role in improving process efficiency and reducing environmental impact. Precious metal recovery and refining machine plants are an advanced solution for companies in the recycling and processing industry for gold, silver, platinum and other noble metals. Thanks to state-of-the-art technologies, every step of the process can be optimized, from the collection of raw material to the production of pure metals.

The importance of precious metals recovery

Precious metals are limited resources that are increasingly in demand in industries ranging from jewelry and electronics to automotive and aerospace. Increasing demand and the need to reduce mining have made the recovery of these materials a strategic and cost-effective activity. Recycling e-waste, scrap metal, and industrial residues makes it possible to obtain precious metals with significantly less environmental impact than traditional mining methods.

Technologies for the recovery of precious metals

Precious metal recovery and refining plants use various technologies to ensure maximum yield and purity of the final product. The main methodologies employed include:

1. Mechanical separation processes.

These processes are used in the initial stage of recovery and include techniques such as:

- Shredding and grinding to reduce materials into smaller fragments;

- Sieving to separate components of different particle sizes;

- Density or magnetic separation, used to isolate ferrous and nonferrous metals.

2. Chemical separation processes.

Highly selective chemical solutions are used to extract and refine precious metals, including:

- Leaching processes: use of chemical agents to dissolve precious metals present in waste materials;

- Electrochemical recovery: use of electrolysis to extract metals in pure form;

- Selective precipitation: chemical reactions that allow selective separation of a particular metal.

3. Pyrometallurgical technologies.

The use of high-temperature furnaces is essential for melting precious metals and separating them from impurities. The most common pyrometallurgical techniques include:

- Smelting and refining with oxidizers: allows impurities to be removed and high-purity metals to be obtained;

- Cupping: a process used to separate gold and silver from lead-containing alloys;

- Refining by chlorination: a technique used to remove base metals and obtain higher purity.

The advantages of modern plants

Companies specializing in the design of precious metal recovery and refining plants offer tailor-made solutions for various production needs. Modern plants provide numerous benefits, including:

- Increased production efficiency: automated processes reduce waste and optimize processing times;

- High purity of recovered metal: thanks to advanced technologies, materials with purity grades up to 99.99 percent are obtained;

- Environmental sustainability: modern plants reduce the use of toxic chemicals and minimize waste generation;

- Process versatility: plants can be adapted to process different types of materials and alloys, providing greater operational flexibility.

Industrial applications

Precious metal recovery and refining plants find applications in numerous industries, including:

- Electronics industry: recovery of gold and silver from discarded printed circuit boards and electronic components;

- Gold industry: recycling of production waste and used jewelry to produce new alloys;

- Automotive industry: recovery of platinum, palladium and rhodium from spent catalysts;

- Chemical and pharmaceutical sector: use of facilities to process catalysts containing precious metals.

Sustainability and industry regulations

Companies involved in precious metal recovery and refining must comply with increasingly stringent environmental regulations. Compliance with international directives, such as the REACH Regulation and European electronic waste (WEEE) regulations, is essential to ensure a sustainable and safe business. In addition, many companies adopt ISO-certified processes to ensure high standards of quality and safety.

Conclusion: precious metal recovery and refining machine plants

Precious metal recovery and refining machine plants are a strategic solution for the recycling and refining industry. Thanks to technological innovation, high-purity metals can be obtained with increasingly efficient and sustainable processes. Investing in advanced facilities not only improves the profitability of companies in the industry, but also helps reduce environmental impact and enhance the value of existing resources. If your company is looking for cutting-edge solutions, relying on experienced partners in the design of recovery and refining plants is the winning choice for a more sustainable and competitive future.